Everything You’ve Ever Wanted to Know About Railings But Are Too Afraid to Ask

Have you ever seen a railing and thought, “Where did these things come from… I mean REALLY come from?” If so, then you should probably find a new hobby, but also you’ve found the right place!

In all seriousness, if you’re going to drop some change into your project with some long-lasting aluminum rails, the least you could do is learn a little bit about its roots!

Thanks Europe

If you’ve ever traveled across the pond to England, you’ve probably noticed that the people there speak English pretty funny, oh, and that they have wrought iron railings all over the place. Before delving into the inadequacies of iron for railings, especially in outdoor applications, we’re going to take a moment to appreciate the ironworking innovations and aesthetic era that led to their widespread adoption.

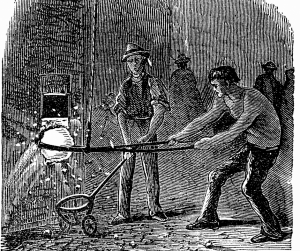

Prior to the 1800s, malleable iron was difficult to produce and much more costly. We credit Henry Cort as the inventor of the Puddling Process, which reduced the carbon content of the raw pig iron and in turn made it into a workable material (“Iron Refining and Puddling Furnaces”).

The ironworkers then feed the iron through rollers to get a nice uniform shape known as, “bar iron.” Many compare the process to rolling dough, except not safe for consumption as evidenced by this excerpt from a 2003 study from the Journal of Clinical Pathology

In 1599, a Spanish governor in early colonial Ecuador suffered this fate. Native Indians of the Jivaro tribe, unscrupulously taxed in their gold trade, attacked the settlement of Logrono and executed the gold hungry governor by pouring molten metal down his throat.

Wow!!!

I’m going to assume you’ve already taken a moment to recover from that thought and proceed.

Armed with malleable and affordable bars of iron, ironworkers rapidly produced all sorts of decorative and functional iron pieces, including railings (obviously), in an effort to meet the insatiable demand from the upper-middle class.

This market wanted to punctuate their affluence by adopting the Victorian designs that were all the rage and by combining wrought iron with cast iron shapes they did just that. Scrolls and finials and filigrees, oh my! Whether they lined yellow brick roads or Buckingham Palace, you could just about find them everywhere and anywhere, even on rooftops!

Back to the Future (20th Century)

That was, until, World War II came around and the public rallied together in scrap drives turning in every bit of unnecessary metal, which unfortunately included these lovely railings (even some from the aforementioned, Buckingham Palace). Of course, the war effort supersedes any decorative fencing, but what makes this story all the more unfortunate is that according to journalist Christopher Long,

“…They never became the guns and tanks they were intended for.”

In fact, I believe that many hundreds of tons of scrap iron and ornamental railings were sent to the bottom in the Thames Estuary because Britain was unable to process this ironwork into weapons of war.

Even in the present day, you can find the remnants of railings that were cut off at their base in various spots throughout London.

The New World

Now if we return to the good ol’ U. S. of A. we can find several beautiful railings of our own and there’s perhaps no better example than those found in New Orleans. Yes, the same New Orleans that’s home to fluffy beignets and “Who Dat!” is also home to some of the most intricate and ornate ironwork.

The city has had quite the contentious past, switching hands from the Chitimacha to the French over to the Spanish then back to the French before finally being sold to the United States (History.com Staff, 2010). As a result, the city became incredibly diverse in ideas, culture, and, of course, design. The Great Fires of 1788 and 1794 also helped to fuel much of that change.

On March 21, 1788 the first of these two fires devastated the city and destroyed 850 of the 1100 buildings. According to Herbert Asbury in The French Quarter

Because the day was Good Friday, the priest refused to allow the church bells to be rung; consequently no alarm was sounded, and the conflagration gained such headway that it could not be checked (39).

The Spanish learned a major lesson with these fires and rebuilt the town using thick brick walls and steel balconies. Within short time, the highly flammable wooden columns and banisters were replaced with wrought and cast iron. Of course, it wouldn’t be like the Spanish to rebuild without an excessive amount of flare.

Would they be content with simple iron rods and flat bars? Nope! Instead they borrowed themes from the rococo style such as lace, coquilles, and fleur-de-lis (Alsup, 2013). In present day metalworking, coquilles is often called “scrolls” and fleur-de-lis is known by “spear” or may be better recognized as the logo for the New Orleans Saints!

With all these neat stories you’ll surely be the coolest kid in your next Bourbon street bar crawl, trust me.

OK, we get it. Iron railings this, iron railings that. You’re reading this because you want to know about aluminum rails, right?? Don’t worry, we’re getting there.

Aluminum… Material for the Space Age

For most people, the word aluminum conjures up the iconic and cherished Coca-Cola can; one of the biggest and earliest applications of aluminum outside of fighter planes and spacecrafts. It’s with good reason that this can is so ubiquitous.

Aluminum does not corrode or rust, it’s one-third the weight of steel, and it’s malleable. In the early part of the 20th century and onwards to present day, aluminum has been highly sought after owing to its versatility and reliability.

If you’re thinking that highly sought after is a euphemism for pricy, then you’re absolutely right. In the 1800s aluminum was considered a luxury item, “The produced metal resembled silver, it was light and expensive, hence at that time aluminium was considered an elite material intended for ornaments and luxury items,” (UC RUSAL).

Only in the recent decades has efficient production and strong recycling efforts helped ease the price point into the consumer-friendly range. This is one of the reasons why aluminum railings took so long to steal the spotlight from iron railings.

Picture it: Miami Beach, 1978. Art Deco architecture and pastel paint jobs line the bustling streets. Beachgoers resting on wrought iron balcony rails to catch the ocean breeze. Sounds idyllic, right? Until you fast forward 30 years and find that those same rails are barely holding on and covered in rust, despite several new paint jobs.

What a buzzkill, am I right?

This pest, commonly referred to as rust, takes a while to really creep in and ruin your day. In these times, iron was the de facto material simply because it was cheaper and the long term costs hadn’t really been considered. With our current understanding of corrosion, one would be foolish to consider anything but aluminum on their project, unless they don’t care about protecting their investment.

To recap: aluminum doesn’t rust and it’s currently competitively priced with any alternatives. So why isn’t everyone using it? Well, the only reasons I can think of are (1) they don’t think it’s strong enough, (2) personal preference, (3) no reliable local aluminum product fabricators, and (4) just plain ol’ ignorance.

Concerning strength, our aluminum products – made of 6061 alloy – meet and exceed the Miami-Dade building code. This code is designed to withstand some of the most brutal hurricanes. Time and again, in the battle between our rails and the big storm, our rails are the victor.

Point being…

Aluminum rails when done correctly can be as strong, if not stronger, than its iron counterpart.

Concerning preference, wrought iron does have its aesthetic charms. Of course, these designs can be replicated in aluminum.

For those that really want the steel look, my only hope is that they at least go with stainless steel and make sure their supplier uses the right alloy. For stainless steel rail systems we use 316, which is much more resistant to corrosion in Miami’s and the Caribbean’s salty environment.

Concerning sourcing reliable aluminum work, say no more!

Railco ships and exports internationally. And, no matter where the destination, we always follow our Miami fabricating standards to make sure your product lasts.

And finally, concerning lack of knowledge, I hope all this information will help you make an educated decision on your next project or renovation!